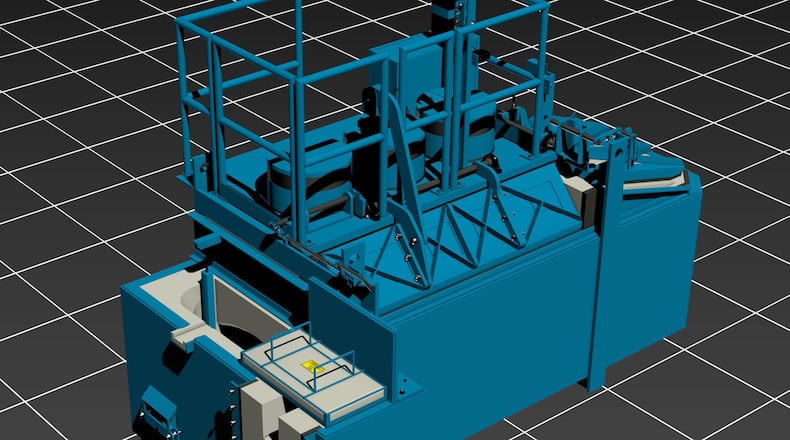

Using virtual reality, a company like human factors engineering firm Beville Engineering in Centerville can design an oil refinery control room in new ways. Or the Schaefer Group in Beavercreek can design an industrial furnace.

RELATED: Summit: 3D printing will bring factories of future

When users don the right headgear and hold hand controllers, they can immerse themselves in that refinery control room — or a virtual version of it — “walking” around any part of the room, checking out desks and monitors, walking through doors. Or they can “walk” inside a Schaefer-designed furnace.

“It’s the difference between getting in a car and just walking around it,” said David White, national sales manager for the Schaefer Group.

If a picture is worth a thousand words, virtual reality is “even better,” he said.

“In a virtual reality world, they can actually make this (an industrial furnace) the physical size it’s going to be,” White said. “I can walk around it and say, ‘OK, this is 10 feet long.’”

That’s especially helpful with customers who are far from Ohio. Much of Schaefer’s business is in Mexico.

“There’s still a place for 3-D animation, but this completely one-ups that game,” said Barb Castilano, owner of Marketing Options.

Marketing Options engineer Brian Judd said he takes 3-D computer assisted drawings from clients to make the virtual reality environments.

RELATED: AFRL ramps up small biz outreach

“The 3-D CAD is really essential,” Judd said. But he added that he can create the immersive virtual reality environments from two-dimensional drawings, too.

Dave Strobhar, owner of Beville Engineering, said building a refinery control center is a “once-in-a-generation” project, with centers expected to perform for 25 to 30 years. Some of them oversee dangerous operations, like taking in 10 million gallons of oil a day and heating it to 900 degrees.

“If I (design) it in just a drawing and lay it out, it’s very difficult to get the perspective on distances, on relationships,” Strobhar said.

Strobhar said his company is part of a consortium of oil and chemical companies that is focused not just on performance, but on safety. Virtual reality can help there.

“How do we get better operators,” Strobhar said. “How do we make them perform better in here? Obviously, one of the key places that’s happening is in the control room.”

SOCIAL MEDIA: Follow Business Reporter Thomas Gnau on Facebook

White agreed.

“We get into some complicated, high-voltage things, that we want to do some virtual training on rather than hands-on (training) first,” he said.

When it’s crucial to get original designs right, more than one virtual reality version of the same potential space can be created, giving customers more choices. Virtual reality lets people gauge alternate layouts in a realistic ways, Strobhar said.

“You don’t want to spend more on one space than you need,” he said.

And the cost of this technology?

For total travel equipment and presentation costs, investments will range from $5,000 to $8,000, Castilano said. That includes a one-time expense on equipment of about $4,000. Software is included.

RELATED: Research aims to keep older aircraft flying

Work on a technical training manual for Beville led to the idea of harnessing virtual reality, Castilano said.

“We went to them,” she said. “We said, ‘We’re looking to get into virtual reality. We think your technical training has a really big hole for virtual reality.’”

Beville agreed. White said Schaefer has found some training uses for virtual reality, too.

White intends to take his virtual reality tools to a trade show in April to give prospective customers a look at company designs. The company hopes to set up a separate “VR booth” to showcase its products that way, he said.

“Everybody else just hands out literature,” White said with a smile.

FIVE QUICK BUSINESS READS

About the Author