Ventilators have been in dangerously short supply as the coronavirus spreads throughout the country. The United States currently has 200,000 ventilators, according to the Society of Critical Care Medicine, but the organization projects about 960,000 patients will need the machines over the course of the epidemic.

Coronavirus: Complete Coverage

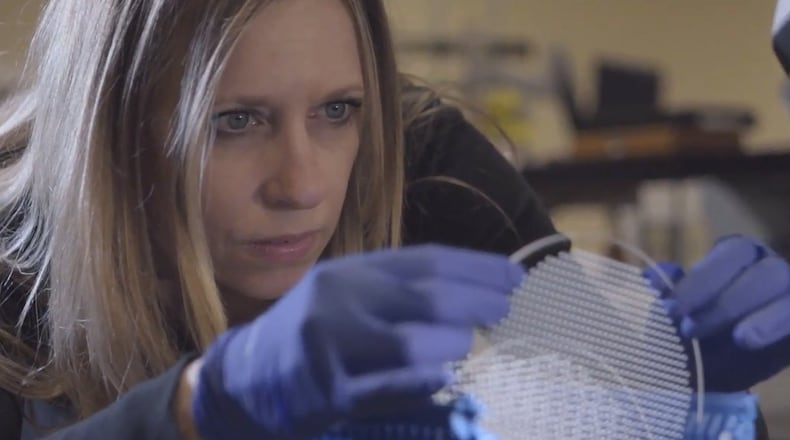

Bullen makes an important part that is used in pressure sensors found in ventilators, which help to measure the air and oxygen pressure to and from a patient.

That makes it one of the many “essential businesses” that have been allowed to remain open in the wake of Ohio Governor Mike DeWine’s widespread shuttering of businesses to combat the epidemic.

But Bullen isn’t just an “essential business” because it manufactures parts for ventilators. It’s other products are used for defense, aerospace and semiconductors – all of which are considered essential, Bullen President Tim Beatty said in an interview. He said the company only recently found out that some of the parts were utilized in ventilators, and that the pandemic has changed the scope of its operations.

“We’re putting an expedited focus on these particular parts to get through,” Beatty said. “They’re products on which we didn’t have existing production lines, so we’re having to really ramp up that production quickly from beginning to finish.”

Staying open in the midst of a pandemic, however, comes at a risk: Bullen’s employees have to come in to work and can’t as easily practice social distancing as a result.

MORE: What coronavirus means for local seniors and services

“While we are committed to serving our nation on a large-scale, we are not taking the threat of COVID-19 on our employees lightly,” Beatty said in a release. “The nature of our work has always driven us to have a healthy and clean facility, and we are enforcing extra measures in light of the pandemic to further prioritize their health and well being.”

Bullen is having its employees work from home when they can, but is also going to great lengths to keep its employees who do come to work healthy. The company has set up temperature checks for every employee coming into work. Bullen leadership have also bought a touchless clock-in system and ramped up cleaning in the building. Workspaces are now sanitized twice per shift.

Bullen isn’t the only company that’s shifting its focus toward fighting the coronavirus. Andrew Doehrel, the president and CEO of the Ohio Chamber of Commerce, said in an interview that he’s seen entire supply chains shift to take on the pandemic.

Doehrel referenced a company that makes plastic containers for shampoo and other products shifting its production toward bottles for hand sanitizer. That in turn meant the company providing the resin to make those bottles had to ramp up its production as well, he said, pointing out how deep supply chains run.

Bullen, which is part of the supply chain to make the critically important ventilators, has risen to the challenge, Doehrel said, but added that the private sector’s work often goes unnoticed.

“Sometimes it can be so simple that we can’t see it,” he said.

Some of Bullen’s customers are Fortune 50 and 100 companies, Beatty said. Roger Geiger, the Ohio executive director of the National Federation of Independent Business, said small businesses are often the backbone of supply chains leading all the way up to some of the nation’s largest companies.

“The supply chain for a lot of the big companies that we hear of so often … their whole supply chain, the people who supply them with the nuts, bolts, pallets, transportation, widgets, whatever it might be, they all come from the small business supply chain,” Geiger said.

RELATED: Coronavirus: Ohio could see as many as 10,000 new cases a day, Acton says

While Bullen’s work will impact the whole country, Beatty said being able to stay open will also help the local economy. Some industries that have been heavily impacted by the economic fallout from the pandemic, like airlines, have had to lay off workers.

“The direct benefit, of course, is keeping the economy going,” Beatty said. “The direct impact is being able to provide employment for people in a time when that is not guaranteed.”

About the Author