RELATED: GE Aviation opens new Dayton research site.

In addition, the amount of ceramic matrix composite (CMC) raw material used for GE Aviation will be some 20 times greater this year than it was in 2007, the company said.

GE Aviation said it is on “the final phase to create its most vertically integrated, new material system ever introduced in the United States.”

RELATED: GE Aviation hails $2B order.

By 2020, GE Aviation is projected to have more than 750 U.S. employees dedicated to its CMC industry.

In 10 years, GE Aviation has spent more than $1.5 billion to bring CMC technology to market. Beyond GE’s Global Research Center in New York, this investment includes four production facilities, including a lab in Evendale Ohio.

RELATED: Ohio firms impacted by Import Bank fight

Now, GE Aviation is building a full-rate production raw material facility in Huntsville, Ala.

Once operational, the Huntsville site will produce up to 20 metric tons, 20,000 kilograms, of CMC material a year.

One CFM LEAP engine uses about 1 kilogram of CMC material.

The GE Aviation Huntsville team has 24 employees. Once fully operational, the Huntsville facilities will employ up to 300 people.

Advanced Silicon Carbide Fiber, a GE Aviation joint venture, will sell fiber manufactured in Huntsville to the Department of Defense, GE businesses, Safran and other external customers. The partners will have the opportunity to become equity partners in the Huntsville plant.

“CMCs in the engine can translate into millions of dollars of annual savings for airline fleets,” the aviation company said. “A 1 percent reduction in fuel consumption can save more than $1 million a year for commercial air carriers. This next generation CMC material technology being produced by GE Aviation will improve fuel efficiency at 1 to 2 percent.”

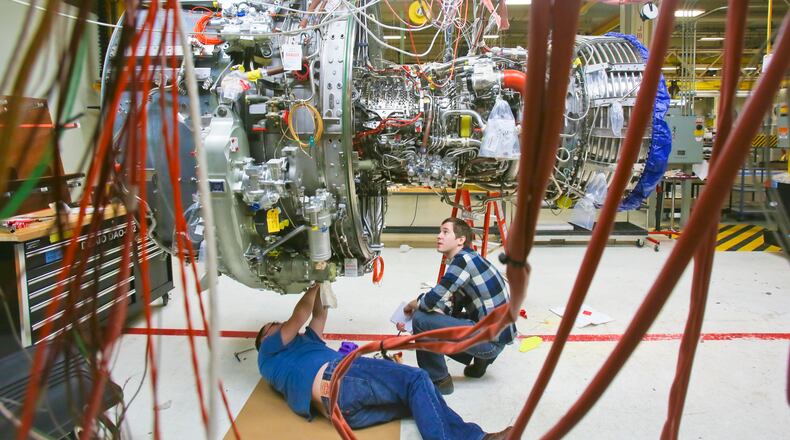

The LEAP engine, developed by West Chester Twp.-based CFM International, the 50-50 joint company of GE and Safran Aircraft Engines of France, is the first commercial jet engine to use CMCs in the high-pressure turbine section, GE Aviation said.

GE Aviation is a major employer in Dayton, Southwestern Ohio — and beyond.

FIVE NEW BUSINESS READS

About the Author