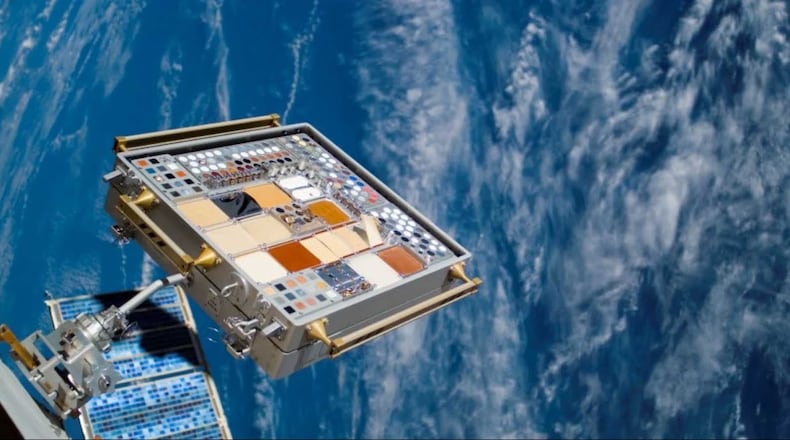

Back in April, a carrier holding the CRG sample materials was mounted to the exterior of the space station by a robotic arm, open to space, where the materials will remain for about six months, the company said.

It’s part of a new materials experiment involving NASA and other research entities to test the performance and durability of materials in the vacuum of space, CRG said.

CRG said it has provided 11 SMP samples, each measuring 3-by-3 inches, of two composite material formulations. These samples were selected based on their potential applications in lunar and Martian environments, the company said.

“The data collected from this mission will be invaluable as we continue to innovate and develop solutions for the unique challenges of space exploration,” said Jason Hermiller, vice president of advanced materials and manufacturing at Cornerstone.

Privately held Cornerstone has focused on defense contracting and manufacturing with research and development, and has been known in the Dayton area for spinning off or nurturing a list of companies since the 1990s: Spintech Holdings, Rushlight Ventures, Advantic, Kineticure, Lectratek, PositAssets and others.

SMP composites combine polymers with reinforcing components to exhibit the ability to return to a predetermined shape when exposed to stimuli, such as heat, light or electrical current.

Cornerstone says these can be useful in applications requiring adaptability and resilience, such as biomedical devices, aerospace structures or “smart textiles.”

The composites being tested will be a foundational component of a new self-aligning, thermally activated reversible joint suitable for various extraterrestrial construction activities.

The goal of this experiment is to compare the performance of pre-flight and post-flight samples to assess the impact of space exposure.

If successful, the Miami Twp. firm says it plans to build parts from space-exposed samples and compare them to samples that haven’t been exposed to space.

“This experiment is a crucial step in advancing our SMP composites towards practical applications in space,” said Evan Gin, a team lead and research engineer at CRG. “We are excited about the potential implications for space debris management and robotic assembly tasks.”

Five space agencies from 15 countries operate the International Space Station, which has been occupied since late 2000.

Each day, the space station makes 16 orbits of Earth, traveling through 16 sunrises and sunsets.

More than 20 different research payloads can be hosted outside the station at once, according to NASA.

About the Author