“Hydration is one way we can understand a person’s susceptibility to heat stress,” said Jeremy Ward, a materials scientist on the Advanced Development Team at the AFRL Materials and Manufacturing Directorate and government lead for the NBMC. “One approach to learning about a person’s hydration status is by monitoring the composition of their sweat.”

The field of wearable technology has grown significantly over the past few years, attracting the interest of industry, academia and military researchers keen on finding ways to better understand how biology and technology can augment the understanding of human performance across the spectrum.

For the Air Force, the ability to better understand a warfighter’s physiological state in the operational environment can not only help improve overall performance but may also help identify potential safety issues, such as dehydration, before they have a chance to impact activity during operational events.

“Heat stress can impact Airmen during training activities as well as in the field of operation. This patch could serve as tool that can help us better understand hydration status in a noninvasive way,” said Ward.

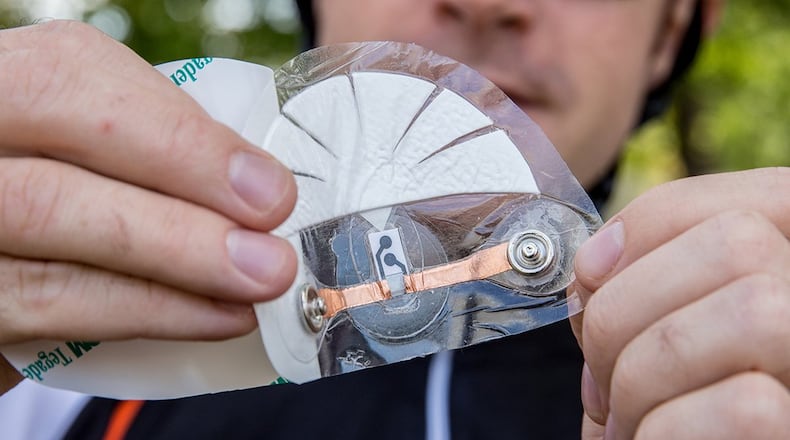

The sweat patch, which adheres to a person’s skin during activity, is enabled by advancements in microfluidic design for sweat transport, next-generation sensor materials and through novel integration concepts for reliable connections between flexible and electronic components of a system. As an individual moves and begins to perspire, the sensor embedded in the patch monitors the potassium and sodium excreted in sweat and transmits this information wirelessly to a mobile device or computer.

“Sodium and potassium increase and decrease depending on time and activity. We can watch these levels go up and down from a distance in real time,” said Ward.

Development of the patch, a team effort since 2014, sought to address a number of materials and processing challenges, according to Ward, particularly as the understanding in the field of flexible, wearable electronics continues to evolve rapidly across academia and industry. One ongoing area of improvement, augmented by the expertise on the AFRL Advanced Development Team, centers on the performance and reliability of the sensor technology embedded in the pad.

“The sensor is a multi-material and multi-layer component of the patch that must maintain the ability to both accurately sense the electrolytes of interest and convert the electrolyte concentration to an electrical signal for transmission of the sweat data wirelessly for analysis. This functionality requires that the sensor materials are selective and reliable,” said Ward.

The first generation of the patch was laboratory tested with simulated sweat by the GE Global Research Team. Additional physiological performance testing occurred under Dr. Adam Strang at the AFRL 711th Human Performance Wing’s Signature Tracking for Optimized Nutrition and Training Laboratory.

A field test of the device took place this March in Colorado Springs, Colorado, through a collaboration between the AFRL’s Materials and Manufacturing Directorate, the 711th Human Performance Wing and U.S. Air Force Academy cadets. This multi-day testing event provided the researchers key information on the ability of the patch to perform in a relevant Air Force environment. Academy cadets wore the patch during a three-hour workout that included a run through the academy obstacle course, a one-and-one-half mile ruck march and a series of callisthenic exercises that included pull-ups, push-ups and sit-ups.

“This was a great opportunity for us to better understand the environment in which our sweat sensors need to operate reliably,” said Ward. “The data from this test has already shaped our research and development efforts moving forward.”

The team has started work on the next generation of the sweat patches, which will take a similar form factor but aim to be thinner, more robust and will incorporate additional sweat assessment capabilities. As they mature the technology, the team will be exploring the possibility to enable the commercialization and transition of the next-generation sensor materials with industry partners in the healthcare and fitness realms.

In any case, the sweat patch is a revolutionary tool in the AFRL research arsenal, with the potential to lead to better understanding of hydration and human physiology for greater safety and performance on the battlefield.

“We’ve been able to advance our understanding of flexible hybrid electronics and sensor materials through this project, which is expected to produce reliable data for human performance monitoring. As we develop more reliable sensor materials and robust packaging concepts, we can provide additional health and safety monitoring applications for DoD training pipelines and communities,” said Ward. “Our work, alongside strong partnerships with the both the 711th Human Performance Wing and industry, has the potential to provide positive impacts to the Air Force and will continue to benefit the warfighter through the future.”

The sweat patch development team received the 2018 FLEXI Award for R&D Achievement at the SEMI Flex Conference and Exhibition in Monterey, California. FLEXI awards recognize groundbreaking accomplishments in the Flexible Hybrid Electronics sector. The award-winning team is comprised of researchers from the Air Force Research Laboratory, GE Global Research, UES, Inc., the University of Arizona, University of Connecticut, University of Massachusetts Amherst and Dublin City University.

About the Author