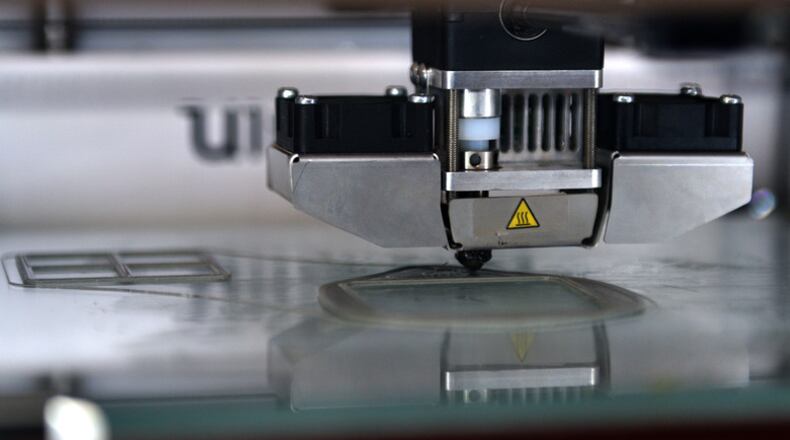

The idea is simple: Help the warfighter quickly reproduce or reverse-engineer crucial parts — parts that in some cases may be years old and perhaps no longer readily available.

The Air Force is looking for solutions fast. White papers on the subject are due Jan. 25, with a request for proposal scheduled to be issued Feb. 4. Proposals from interested experts are due March 5, and the Air Force expects to choose a solution by the end of March. (The commercial solutions opening can be found at beta.sam.gov or at this link.)

Air Force leaders have long been sold on the power of 3D printing. Will Roper, Air Force assistant secretary for acquisition, technology and logistics, has talked of making critical spare parts for weapon systems of all kinds with 3D printing.

“Additive and advanced manufacturing (has) been going like gangbusters across the Air Force and Space Force — printing thousands of parts for airplanes,” Roper said in May. “We’re starting to print parts for satellites, including propulsion.”

Stacy Betlej-Amodeo, who focuses on advanced manufacturing in the Rapid Sustainment Office at Wright-Patterson Air Force Base, said her office and the Air Force are concentrating on what Airmen need now.

“We’re working to get technology into the hands of the warfighter,” she said.

Some of these parts are difficult to source today. Yet the Air Force still depends on the planes and equipment from which these parts come.

“It’s no secret that we have an aging fleet,” Betlej-Amodeo said.

The ability to model and print aircraft parts on battlefields is one possible scenario. “How do you keep the supply chain moving in a contested environment? AM (additive manufacturing) certainly has the potential to enable that.”

But in the near term, she said the primary focus is a “very real sustainment needs that our aircraft and Airmen face day-to-day.”

One of the best aspects is the ability to bypass a good deal of tooling, said Ben Staub, president of Vandalia prototyping manufacturer (and 3D printing company) Bastech.

“The biggest thing about 3D printing for sustainment is, you don’t have to go through all the traditional tooling,” Staub said. “A lot of castings, metal parts and even plastic parts need significant tooling and engineering design and that type of thing, which takes months and months to build.”

“The best of part that is, if somebody comes up and says, ‘OK, I need this fuel nozzle for an old jet that we don’t have anymore — and nobody can find all the drawings and tooling and everything else,’ then we can literally reverse-engineer it with laser scanning, get that data and build it on a 3D printer,” he added.

“We are working closely with the University of Dayton Research Institute (UDRI) to develop the technical data and print 3D parts to meet current needs right now,” Betlej-Amodeo said.

UDRI’s work in this area is well known. Tim Osborn, a UDRI group leader in additive manufacturing technology development, said in 2019 that 3D printing can often be used to sustain planes by quickly replacing parts.

In a video, Osborn described how UDRI uses a laser scanner to create a model of a part that needs to be replicated, using a handheld Creaform HandyScan device. The 3D file generated is then moved into a computer program for modifications before going to a 3D printer.

“The benefit is really just-in-time inventory control — having the parts when you need them is perfect for aerospace sustainment,’ Osborn said.

The Air Force printed in 2020 alone more than 1,500 parts for weapons systems, including metal and polymer parts. That represents a 59% increase over what the force printed in 2019, Betlej-Amodeo said.

The solution the Air Force wants needs to include a manual and an online training course. It should address any anticipated hardware and software tools necessary to scan parts with complex geometry, various surface color and reflectivity, and “provide a means to address part geometry that cannot typically be scanned, for example, blind holes and internal/hidden geometry.”

“The resulting solution should allow trained USAF users to create accurate 3D models capable of being easily utilized, manipulated and/or modified for additive manufacturing purposes utilizing common commercially available CAD (computer assisted design) software,” the call said.

The commercial solutions opening can be found here.

About the Author

![After printing various parts with AF-9628 powder, Capt. Erin Hager analyzed the resulting porosity, strength and impact toughness. She noted that the mechanical properties were quite good. She “didn’t see cracking,” and asserts that, [the output] was very similar [to traditionally manufactured parts]. In fact, the parts “matched the required 10 percent elongation, indicating increased strength without becoming brittle,” and “met or exceeded [specifications] straight out of the machine.” (Courtesy photo/Air Force Institute of Technology)](https://www.daytondailynews.com/resizer/v2/5P2IPOFSQJA4ZLL4BKJD64CGKM.jpg?auth=2eb8c1a4f0122a6464abe2acce93599b8645a782aa0fcb3bee95ada559cd22dd&width=1600&smart=true)