The 18-foot-long Northrop Grumman engine endured a half hour of accumulated combustion time during the nine months of testing.

“The series of tests, ran in conjunction with AEDC and AFRL, on this fighter-engine sized scramjet was truly remarkable,” said Pat Nolan, vice president, missile products, Northrop Grumman. “The scramjet successfully ran across a range of hypersonic Mach numbers for unprecedented run times, demonstrating that our technology is leading the way in delivering large-scale hypersonic platforms to our warfighters.”

“The plan for a larger and faster hypersonic air breathing engine was established 10 years ago during the X-51 test program, as the Air Force recognized the need to push the boundaries of hypersonic research,” Barhorst said. “A new engine with 10-times the flow of the X-51 would allow for a new class of scramjet vehicles.”

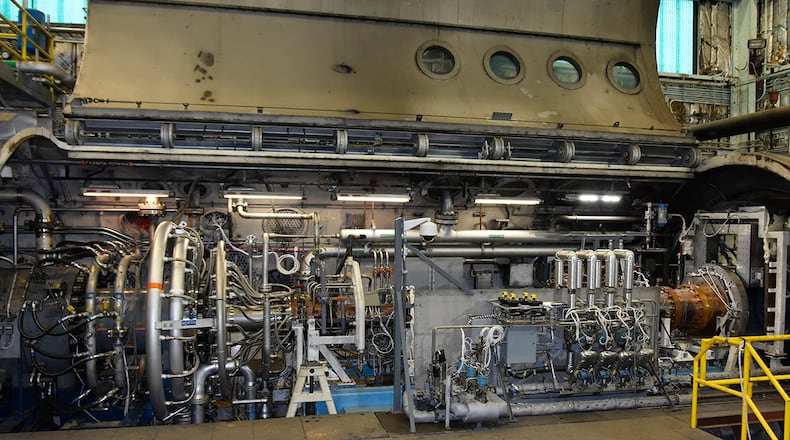

An evaluation of the nation’s test facilities concluded that none could test an engine at this large of a scale in a thermally-relevant environment. To address the issue, AEDC’s Aerodynamic and Propulsion Test Unit facility underwent a two-year upgrade to enable large-scale scramjet combustor tests over the required range of test conditions. The AEDC team also successfully leveraged technology developed by CFD Research Corporation under the Small Business Innovative Research program. This technology proved crucial in achieving most of the required test conditions.

“Our collective team has worked hard over the past few years to get to where we are today,” said Sean Smith, lead for the AEDC Hypersonic Systems Combined Test Force ground test team. “We’ve encountered numerous challenges along the way that we’ve been able to overcome thanks to the dedication and creativity of the team. We’ve learned quite a bit, and I’m proud of what we’ve accomplished. These groundbreaking tests will lead the way for future hypersonic vehicles for a range of missions.”

“After years of hard work, performing analysis and getting hardware ready, it was a great sense of fulfillment completing the first successful test of the world’s largest hydrocarbon fueled scramjet,” added Barhorst.

About the Author